Chi siamo

-

Via Piani di Marischio, 5

60044 Fabriano (AN) - Tel. +39 (0)732 71104

- Fax +39 (0)732 71082

- info@cm-concretemixers.it

- P.IVA 00990410425

Menu

Menu

The Vibrating Screener has a volumetric production of 30m3/h and is fitted with n.2 vibrators of 5kW each, has a loading hopper of 3m3, 3m long, 2m wide with a bed in polyurethane mesh and at the top a series of spray nozzles optimized for washing away the inert subjected to the vibration process.

The Filter Press consists of a group of n.10 80cm square plates, n.20 support and sliding wheels in polyethylene with easy sliding, n.1 hydraulic pump with 5.5kW motor, 120 litre tank, 250bar service pressure , n.1 automatic shaking system for the detachment and precipitation of dehydrated sludge, filtering capacity 9,000 l/h, electricity consumption 15kW/h, automatic washing system.

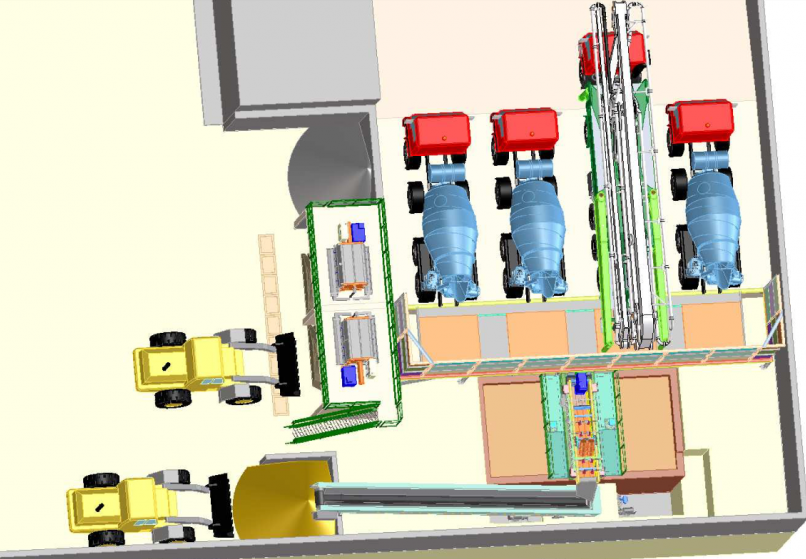

The planimetric configuration of the CMRC plant can be easily adapted to the geometry available on the customer’s work site and on request we can also supply above-ground tanks in galvanized metal for the storage and agitation of waste water.

Chi siamo

© 2023 All rights reserved

Credit by Dedalo Group

I was very pleased to find this web-site.I wanted to thanks for your time for this wonderful read!! I definitely enjoying every little bit of it and I have you bookmarked to check out new stuff you blog post.