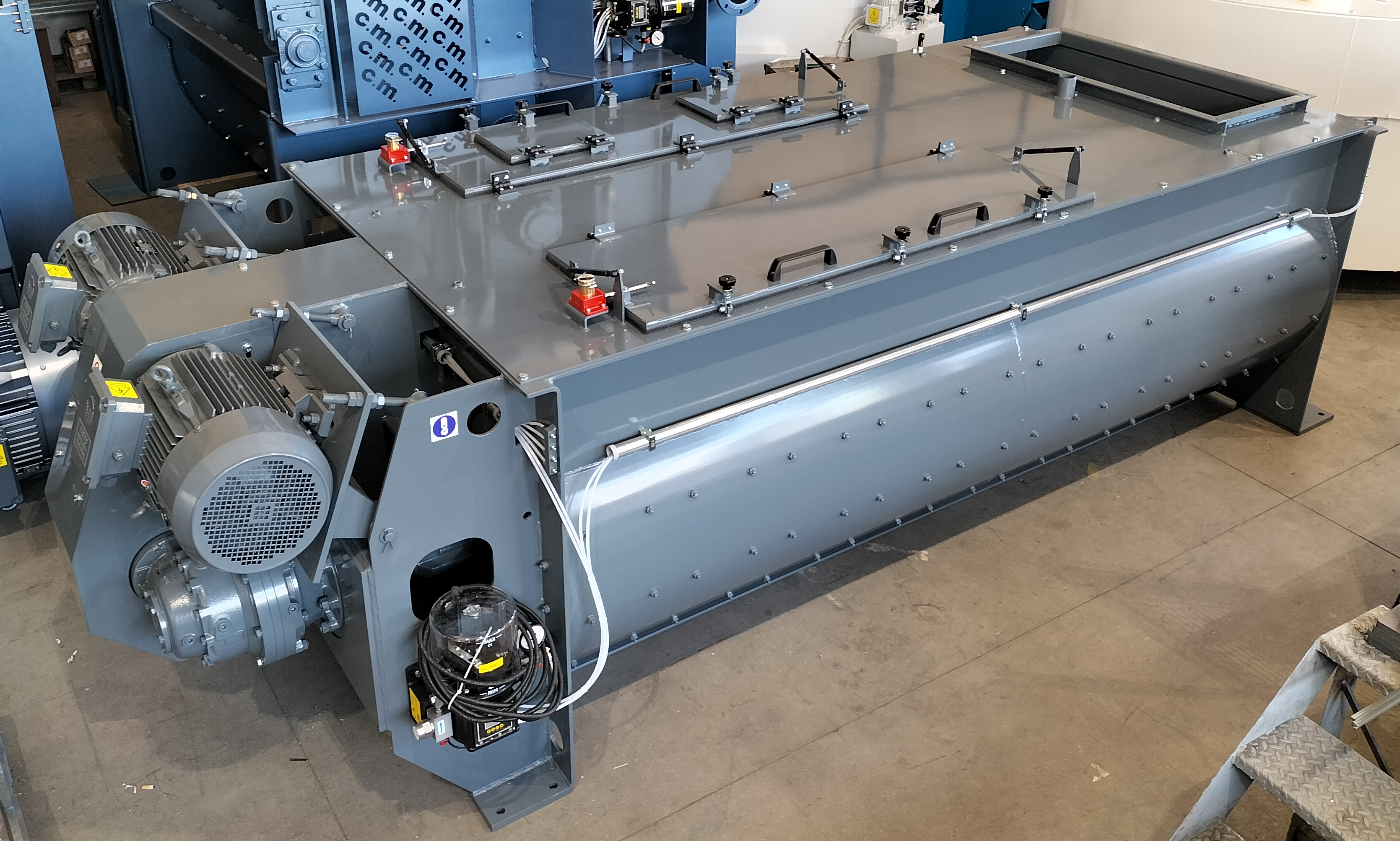

MC – Twin Shaft Continuous Mixer

The horizontal double shaft continuous mixers have elongated tank geometry, the rotation speed of the shafts is much higher than the double shaft cycle mixers, the blades are much more numerous and in this case, in addition to the mixing function, they also have that of advancing the material from the loading area on the opposite side up to the discharge opening through which the material, already mixed, exits by a continuous flow.

They are used for all the production of cement mixes and conglomerates in general with a low binder content, but they are also perfectly capable of producing cold recycled materials from milled bituminous pavements.

In recent years, their use has become common for the inertization of contaminated soils and for the recycling of materials from building demolitions.

Last but not least, it is used for the production of pumpable mixtures intended for filling underground cavities once the raw material extraction phase has been completed.

In recent years, their use has become common for the inertization of contaminated soils and for the recycling of materials from building demolitions.

Last but not least, it is used for the production of pumpable mixtures intended for filling underground cavities once the raw material extraction phase has been completed.

TRANSMISSION

Depending on the size of the mixer, either the system is used with 1 single motor with epicyclic reduction in line associated with a parallel shaft reducer with helical teeth or the system with 2 independent motors elastically associated with two opposite angular reducers connected to each other by the synchronization joint.

Even in this type of mixer, the perfect alignment between shafts and transmission parts is guaranteed by the assembly on specially machined bowl body seats.

Even in this type of mixer, the perfect alignment between shafts and transmission parts is guaranteed by the assembly on specially machined bowl body seats.

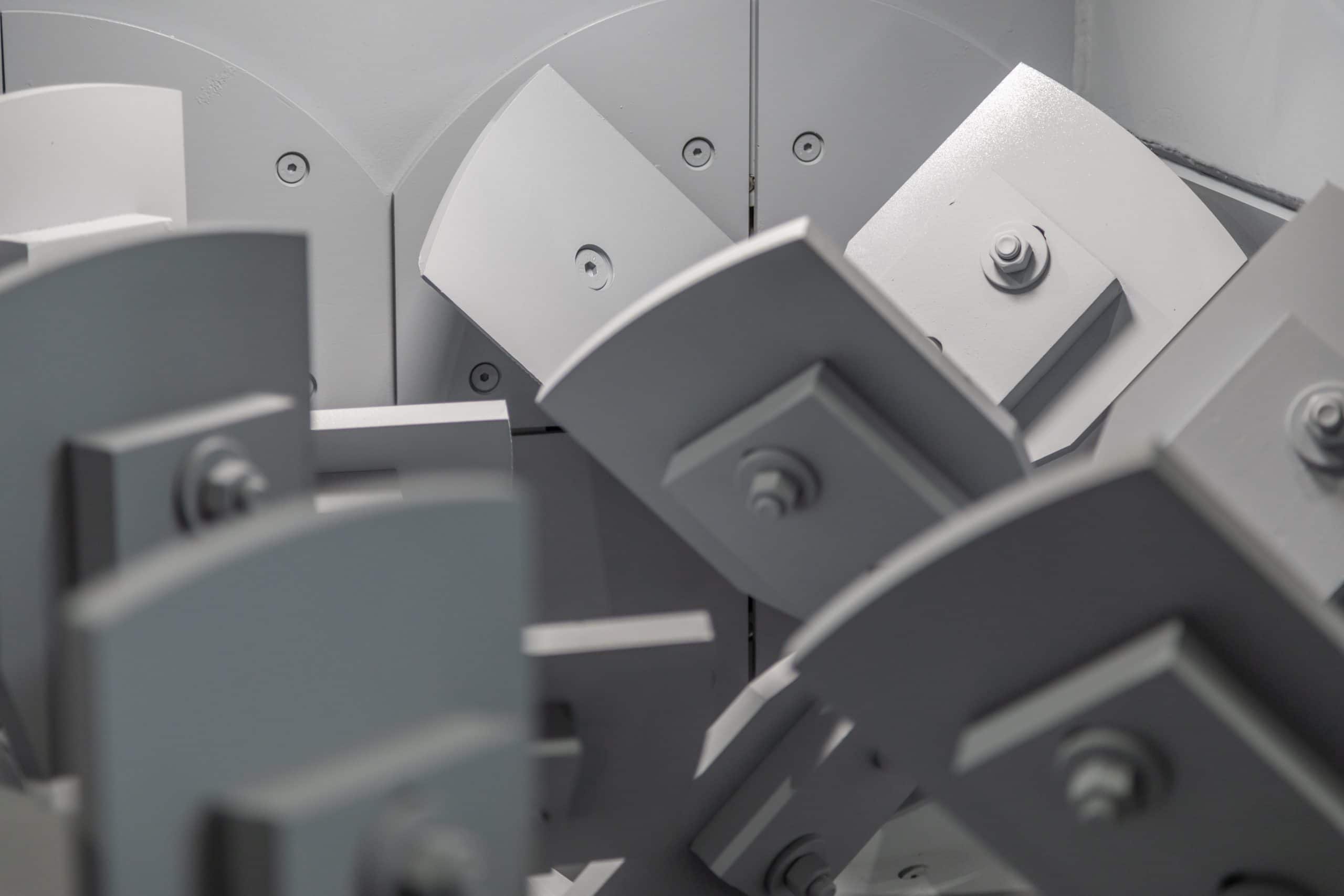

MIXING TOOLS

The following image wants to reaffirm the three-dimensional concept of mixing that is obtained with the horizontal double axis mixers applied in this case to the transit of the material in

continuous.

That is, while the material to be mixed receives the maximum dynamic turbulence in the right-left exchange, and vice versa, it is also moved along the axis of the mixing tank towards the discharge opening.

SHAFTS SUPPORTS

The radial load of the mixing shafts is supported by bearings housed in special seats inside the cast iron supports suitably separated and spaced from the seal packs which prevent grout from leaking.

In this way, even if a maintenance defect occurs with grout leakage, the mixer will never lose its mechanical functionality. The shaft supports are designed in such a way that they can be replaced with the entire seal pack and bearing already integrally pre-assembled (only n.1 piece system).

It is sufficient to insert them on the ends of the shafts and screw the fixing screws on the appropriate connection flanges. Our customers find this system particularly convenient and quick because they don’t have to worry about the correct assembly of all the components inside each support.

In this way, even if a maintenance defect occurs with grout leakage, the mixer will never lose its mechanical functionality. The shaft supports are designed in such a way that they can be replaced with the entire seal pack and bearing already integrally pre-assembled (only n.1 piece system).

It is sufficient to insert them on the ends of the shafts and screw the fixing screws on the appropriate connection flanges. Our customers find this system particularly convenient and quick because they don’t have to worry about the correct assembly of all the components inside each support.

AUTOMATIC GREASING PLANT

As an option, a fully automatic seal lubrication system can be mounted on board the mixer, designed to have safe and constant lubrication inside the mixing shaft supports.

The electrically powered pump and the progressive type distributor are made with materials and geometries suitable for working in outdoor environments and with the presence of a considerable amount of dust and humidity.

Filling of the grease tank is arranged through the passage for a bottom loading filter, filling from above is mechanically prevented in order to prevent the introduction of impurities. The pump body houses a mini PLC with an alphanumeric LED display for the timing and control of the automatic lubrication cycle with the possibility of sending alarm signals remotely.

Filling of the grease tank is arranged through the passage for a bottom loading filter, filling from above is mechanically prevented in order to prevent the introduction of impurities. The pump body houses a mini PLC with an alphanumeric LED display for the timing and control of the automatic lubrication cycle with the possibility of sending alarm signals remotely.

MIXER’S COVER

As standard we have the flat execution of the mixing tank cover with access doors equipped with continuous rubber seal with ample thickness of the rebate and double gas springs for assistance and safety stop when opening.

We build the mixing water distributor pipe into the cover with a sleeve inlet. In accordance with the current provisions of the EC machinery directives on accident prevention safety, all our continuous mixers have a lock mounted on the cover for mechanical blocking of doors opening with a key transfer system coordinated with the device maneuver block, supplied by us, intended to be installed on the release system of the electrical power supply of the mixer in the electrical power panel.

We build the mixing water distributor pipe into the cover with a sleeve inlet. In accordance with the current provisions of the EC machinery directives on accident prevention safety, all our continuous mixers have a lock mounted on the cover for mechanical blocking of doors opening with a key transfer system coordinated with the device maneuver block, supplied by us, intended to be installed on the release system of the electrical power supply of the mixer in the electrical power panel.

Good day! I could have sworn I’ve been to your blog before but after going through some of the articles I realized it’s new to me. Regardless, I’m definitely happy I discovered it and I’ll be bookmarking it and checking back frequently.

Thanks , I’ve recently been looking for information about this topicfor a while and yours is the best I have found out till now.However, what about the conclusion? Are you positive in regards to the supply?

ivermectin dose for head lice does ivermectin kill lyme disease

Could you send me an application form? aztec treasure online slots Lee Metcalf in Washington, D.C., in August 1962, included, from left, Joe Braycich, George Ostrom, Dick Warden, Teddy Roe, Vic Reinersma and Roy Dockstedda

I truly appreciate this blog post.Really looking forward to read more. Much obliged.

Thank you for your blog post.Really looking forward to read more. Awesome.

Major thanks for the blog post.Much thanks again. Much obliged.

I am so grateful for your article post.Really looking forward to read more. Great.

Thanks for sharing, this is a fantastic blog.Really looking forward to read more. Really Cool.

Great post.Really looking forward to read more. Fantastic.

Muchos Gracias for your article. Cool.

Wow, great post.Really thank you! Really Great.

Thanks for sharing, this is a fantastic article post.Much thanks again. Really Cool.

Lovely as always. I love the way you paint with words Deidre Chaunce Gerrit

Do you have a spam issue on this blog; I also am a blogger, and I was curious about your situation; many of us have developed some nice practices and we arelooking to exchange strategies with other folks, be sure to shoot me an e-mail if interested.

It as really a nice and helpful piece of info. I am glad that you shared this useful information with us. Please keep us informed like this. Thanks for sharing.

am cumparat o lucrare licenta plagiata total de la lucrare licenta eu. Vinovat este patronul SC Creativ TRD SRL, neata adrian valentin pentru lucrarea in bataie de joc.

Heya just wanted to give you a brief heads up and letyou know a few of the images aren’t loading properly.I’m not sure why but I think its a linking issue. I’ve tried it in two different internetbrowsers and both show the same outcome.

Good way of explaining, and fastidious post to obtain facts concerning my presentation focus,which i am going to deliver in college.

plaquenil oct hydroxychloroquine – hydroxy-chloroquine

Very neat blog post.Really looking forward to read more. Awesome.

Hey are using WordPress for your blog platform? I’m new to the blog worldbut I’m trying to get started and create my own. Do you need any coding expertise to make your own blog?Any help would be really appreciated!

I enjoy what you guys are usually up too. Such clever workand coverage! Keep up the wonderful works guys I’ve addedyou guys to blogroll.

Great, thanks for sharing this blog.Really looking forward to read more. Want more.

Great, thanks for sharing this blog post.Really looking forward to read more. Really Great.

Hey! I’m at work surfing around your blog from my new iphone!Just wanted to say I love reading your blog and look forwardto all your posts! Carry on the fantastic work!

I love reading through an article that will make men and women think. Also, many thanks for permitting me to comment!

how long after taking ivermectin can you drink alcohol ivermectin dosage for sheep

wow, awesome article.Thanks Again. Great.

Pretty section of content. I just stumbled upon your blog and in accession capital to assert that I get in fact enjoyed account your blog posts. Any way I?ll be subscribing to your augment and even I achievement you access consistently quickly.

It’s difficult to find experienced people for this topic, but you seem like you know what you’re talking about! Thanks

I love what you guys are usually up too. This kind of clever work and coverage! Keep up the good works guys I’ve added you guys to our blogroll.

Now I am going away to do my breakfast, later than having my breakfast coming again to read additional news.

Department Of School Education Haryana Chandigarh Modern Fantasy Children’S Books

The following time I learn a weblog, I hope that it doesnt disappoint me as much as this one. I imply, I know it was my choice to read, however I truly thought youd have something interesting to say. All I hear is a bunch of whining about something that you can repair if you werent too busy on the lookout for attention.

In this great pattern of things you secure an A+ for effort. Exactly where you actually confused us was first on the specifics. As it is said, details make or break the argument.. And it could not be more accurate here. Having said that, permit me reveal to you what exactly did deliver the results. Your text is certainly really engaging and that is probably the reason why I am taking an effort to comment. I do not make it a regular habit of doing that. 2nd, while I can easily notice the leaps in logic you make, I am not necessarily confident of how you appear to connect the ideas which produce the actual final result. For now I will subscribe to your point but wish in the near future you actually connect your facts better.

Nice post. I learn something more challenging on totally different blogs everyday. It is going to all the time be stimulating to read content material from other writers and practice slightly something from their store. I’d prefer to use some with the content on my blog whether or not you don’t mind. Natually I’ll give you a link on your web blog. Thanks for sharing.

I’m not that much of a online reader to be honest but your sites really nice, keep it up! I’ll go ahead and bookmark your site to come back down the road. All the best

A powerful share, I just given this onto a colleague who was doing just a little analysis on this. And he in reality purchased me breakfast as a result of I found it for him.. smile. So let me reword that: Thnx for the deal with! However yeah Thnkx for spending the time to debate this, I really feel strongly about it and love reading more on this topic. If attainable, as you become expertise, would you mind updating your blog with extra details? It is extremely useful for me. Huge thumb up for this weblog post!

I’m not sure the place you are getting your info, but great topic. I needs to spend some time studying more or understanding more. Thanks for excellent information I was on the lookout for this info for my mission.

I do not even know how I ended up here, but I thought this post was good. I do not know who you are but certainly you’re going to a famous blogger if you aren’t already 😉 Cheers!

Keep functioning ,terrific job!

Hi my family member! I want to say that this post is awesome, great written and include almost all significant infos. I would like to look more posts like this .

I have been checking out some of your posts and it’s nice stuff. I will definitely bookmark your site.

Thanks , I have recently been looking for info about this topic for ages and yours is the greatest I’ve discovered so far. But, what about the bottom line? Are you sure about the source?

Im obliged for the article.Much thanks again. Want more.

I appreciate, cause I found just what I was looking for. You have ended my four day long hunt! God Bless you man. Have a nice day. Bye

Hey, thanks for the blog. Cool.

Thanks , I’ve just been looking for information approximately this subject for a while and yours is the best I’ve found out till now. But, what about the bottom line? Are you certain in regards to the source?

Very informative blog post.Really looking forward to read more. Fantastic.

cbd pure cbd tinctures full spectrum cbd oil

Really informative article. Cool.

This is one awesome post.Much thanks again. Really Cool.

ivermectin tablets uk ivermectin 1 cream generic

Im obliged for the blog post. Fantastic.

I cannot thank you enough for the article. Cool.

Have you ever wondered who posts some of this stuff that you come across? Recently it seems to have become an epidemic, although it seems to be changing for the better. Do you agree?

Thanks for the article.Really thank you!

Say, you got a nice article post.Really thank you! Really Great.

Great blog article.Thanks Again. Want more.

Thank you for your post.Thanks Again. Fantastic.

I think this is a real great blog. Awesome.

Say, you got a nice article. Cool.

When someone writes an article he/she retains the thought of a user in his/her brain that how auser can be aware of it. Therefore that’s why this paragraph is amazing.Thanks!

I appreciate you sharing this post.Really thank you! Really Cool.

A round of applause for your blog.Really looking forward to read more. Cool.

Thank you ever so for you blog article.Thanks Again. Awesome.

I value the blog article.Thanks Again. Cool.

I value the blog.Really looking forward to read more. Cool.

A round of applause for your blog post.Really looking forward to read more. Great.

Im obliged for the article.Thanks Again. Much obliged.

A motivating discussion is definitely worth comment.I think that you should publish more on this topic, it may not be a taboo matter but typically people do not talk about such issues.To the next! Best wishes!!

best writing services essay proofreading service

Howdy! I’m at work surfing around your blog from my new iphone 4!Just wanted to say I love reading your blog and look forward to all your posts!Keep up the excellent work!

Really informative article post. Awesome.

Looking forward to reading more. Great article.Really thank you! Really Great.

I don’t even know the way I finished up here, but I thoughtthis publish was great. I don’t know who you might be howeverdefinitely you’re going to a famous blogger for those who aren’t already.Cheers!

I truly appreciate this article post.Really looking forward to read more. Much obliged.

This is a dialect right spellbinding post. Keep them coming. Breena Norrie Kimberlyn

Hi, all is going fine here and ofcourse every one is sharing data, that’s actually good, keep up writing.

Very informative article post.Much thanks again. Really Great.

Enjoyed every bit of your blog article. Keep writing.

I loved your blog article.Much thanks again. Will read on…

Major thanks for the article.Thanks Again.

Fantastic article.Really looking forward to read more. Awesome.

Hey, thanks for the blog post.Thanks Again. Really Cool.

stromectol australia ivermectin 1 topical cream

Thanks again for the blog.Really thank you! Really Cool.

Thanks a lot for the post.Thanks Again. Keep writing.

I like the valuable info you provide in your articles. I will bookmark your blog and check again here frequently. I’m quite sure I will learn plenty of new stuff right here! Best of luck for the next!

I loved your blog.Really looking forward to read more.

In fact no matter if someone doesn’t know afterward its upto other people that they will assist, so hereit takes place.

A company car fame and fortune slots Next season, though, Appleyard played in just one match before breaking down completely

ed new pills – ed pills that start with a v red dragon ed pills

I think this is a real great article post.Thanks Again. Want more.

You completed a number of nice points there. I did a search on the topic and found most people will agree with your blog.

I really like your writing style, fantastic information, appreciate it for posting :D. “Much unhappiness has come into the world because of bewilderment and things left unsaid.” by Feodor Mikhailovich Dostoyevsky.

I am not sure where you’re getting your information, but great topic.I needs to spend some time learning much more or understanding more.Thanks for wonderful info I was looking for this information for my mission.

Major thanks for the blog post.Thanks Again. Fantastic.

Thanks-a-mundo for the article post.Really looking forward to read more. Much obliged.

Hey, thanks for the article.Really looking forward to read more. Keep writing.

I cannot thank you enough for the article post.Thanks Again. Cool.

Good day! I simply wish to give you a huge thumbs up for your great information you have here on this post. I will be returning to your blog for more soon.

I really like it when individuals come together and share views. Great blog, continue the good work! Ardelia Yul Thomasin

Thanks a lot for the blog.Really thank you! Will read on…

Major thankies for the blog article.Thanks Again. Want more.

prednisone over the counter – prednisolone prednisone prednisone online sale

Hi there, yup this piece of writing is actually fastidious and I have learned lot of things fromit regarding blogging. thanks.

Thanks so much for the blog article.Really looking forward to read more. Great.

Muchos Gracias for your article post.Really looking forward to read more.

Thank you for some other informative blog. The place else may I am getting that type of information written in such an ideal manner? I have a project that I’m simply now running on, and I’ve been on the look out for such information.

Major thankies for the blog post.Thanks Again. Really Cool.

You explained this fantastically.how to write the college essay help writing dissertation mba thesis writers

Say, you got a nice post.Really thank you! Much obliged.

Major thanks for the blog article. Really Cool.

Excellent article. I’m experiencing a few of these issues as well..My Blog Post: vách ngăn mica bàn ăn

Good day! I know this is kind of off topic but I was wondering if you knew where I could get a captcha plugin for my comment form?I’m using the same blog platform as yours and I’m having problems finding one?Thanks a lot!

Wow! This could be one particular of the most useful blogs We have ever arrive across on this subject. Actually Excellent. I’m also an expert in this topic therefore I can understand your hard work.

You made your point.essay writing review dissertation writing medical personal statement writing service

I really like your writing style, fantastic information, thank you for putting up :D. “Kennedy cooked the soup that Johnson had to eat.” by Konrad Adenauer.

Really appreciate you sharing this article post.Really looking forward to read more. Really Great.

This is one awesome blog post.Really looking forward to read more.

Im thankful for the blog article.Much thanks again. Want more.

A big thank you for your article post.Really thank you! Really Cool.

I quite like reading through an article that can make men and women think. Also, thanks for allowing me to comment!

I am so grateful for your blog post.Much thanks again. Really Cool.

Really enjoyed this article post.Thanks Again. Fantastic.

Thanks again for the post.Really thank you! Will read on…

Great, thanks for sharing this blog article. Awesome.

What’s up, after reading this remarkable articlei am as well delighted to share my knowledge here with friends.

It’s actually a great and useful piece of info. I am gladthat you simply shared this helpful information with us.Please stay us informed like this. Thank you for sharing.

Thanks for sharing, this is a fantastic post.Really thank you! Awesome.

I cannot thank you enough for the blog.Really thank you! Fantastic.

Thanks-a-mundo for the article post.Really thank you! Really Cool.

Very neat article.

Hey, thanks for the article post.Really looking forward to read more. Really Cool.

Really enjoyed this article.Much thanks again. Cool.

A big thank you for your article. Much obliged.

I think this is one of the most vital info for me. And i’m glad reading your article. But should remark on few general things, The web site style is wonderful, the articles is really nice : D. Good job, cheers

Thank you for your blog. Really Cool.

A big thank you for your post.Really looking forward to read more. Much obliged.

Muchos Gracias for your blog article.Really looking forward to read more. Keep writing.

Fantastic blog article.Really looking forward to read more. Will read on…

I appreciate you sharing this article post.Thanks Again. Great.

Fantastic blog. Fantastic.

Looking forward to reading more. Great blog.Really thank you!

Super-Manufacturer.com currently features over 70 million product listings across 27 industries worldwide. We provide diverse product search and sourcing options tailored to the needs of global buyers, ensuring you can quickly find the high-quality products you need.

I?¦ve read a few excellent stuff here. Certainly value bookmarking for revisiting. I wonder how a lot attempt you set to make any such great informative site.

Fantastic web site. Lots of useful info here. I’m sending it to several friends ans also sharing in delicious. And naturally, thanks for your effort!

Great V I should definitely pronounce, impressed with your web site. I had no trouble navigating through all tabs as well as related information ended up being truly simple to do to access. I recently found what I hoped for before you know it at all. Reasonably unusual. Is likely to appreciate it for those who add forums or something, website theme . a tones way for your customer to communicate. Nice task..

магазин аккаунтов социальных сетей купить аккаунт с прокачкой

услуги по продаже аккаунтов аккаунт для рекламы

Account Catalog Social media account marketplace

Buy and Sell Accounts Website for Selling Accounts

Precisely what I was searching for, regards for posting.

Website for Selling Accounts Online Account Store

website for selling accounts profitable account sales

purchase ready-made accounts website for selling accounts

account purchase sell accounts

sell accounts buy-soc-accounts.org

I cling on to listening to the newscast talk about receiving boundless online grant applications so I have been looking around for the top site to get one. Could you tell me please, where could i find some?

account acquisition gaming account marketplace

account market account buying platform

fabuloso este conteúdo. Gostei bastante. Aproveitem e vejam este conteúdo. informações, novidades e muito mais. Não deixem de acessar para saber mais. Obrigado a todos e até mais. 🙂

buy accounts https://accounts-marketplace.xyz

accounts marketplace https://social-accounts-marketplaces.live/

Hello colleagues

Hello. A 14 perfect website 1 that I found on the Internet.

Check out this website. There’s a great article there. http://www.photoshop-weblog.de/webdesigntrends-2022-die-wichtigsten-designtrends-fuer-das-kommende-jahr/|

There is sure to be a lot of useful and interesting information for you here.

You’ll find everything you need and more. Feel free to follow the link below.

ready-made accounts for sale accounts marketplace

I simply desired to thank you very much all over again. I’m not certain the things I would have tried without the entire tips and hints documented by you concerning that field. It previously was a hard dilemma for me personally, nevertheless being able to see this skilled strategy you dealt with it took me to leap with contentment. Now i am happy for the service and thus hope you really know what an amazing job you are always accomplishing teaching people through a web site. I am sure you have never met any of us.

sell pre-made account https://accounts-marketplace-best.pro

buying facebook ad account https://buy-adsaccounts.work

fb accounts for sale https://buy-ads-account.click

facebook ad account buy cheap facebook accounts

buy aged fb account facebook ad accounts for sale

buy google ads verified account https://sell-ads-account.click/

buy facebook business manager verified https://buy-business-manager-acc.org/

unlimited bm facebook verified-business-manager-for-sale.org

buy tiktok business account https://buy-tiktok-ads-accounts.org

My spouse and i were cheerful John could finish off his investigation out of the precious recommendations he received from your blog. It is now and again perplexing to just always be freely giving information and facts that many many people could have been trying to sell. We really consider we need you to appreciate because of that. The most important illustrations you’ve made, the easy site navigation, the relationships you make it easier to instill – it’s got everything superb, and it is leading our son in addition to the family reckon that that situation is satisfying, which is certainly extraordinarily essential. Thanks for the whole lot!

I intended to create you a little bit of note to say thanks a lot the moment again about the pleasant tactics you’ve featured here. This has been certainly particularly open-handed with you to provide openly all a lot of folks could possibly have distributed as an e-book to get some dough on their own, most importantly considering that you could have tried it in the event you decided. These tips additionally worked to become easy way to comprehend other people online have a similar dream just as mine to understand significantly more with regards to this problem. Certainly there are a lot more enjoyable opportunities up front for folks who read your blog post.

I’m not sure where you are getting your info, however good topic. I needs to spend some time studying more or working out more. Thanks for excellent info I was on the lookout for this info for my mission.

Oh my goodness! an incredible article dude. Thanks Nevertheless I am experiencing difficulty with ur rss . Don’t know why Unable to subscribe to it. Is there anybody getting similar rss downside? Anybody who knows kindly respond. Thnkx

inderal online pharmacy: rite aid pharmacy how many store – pharmacy in artane castle

sildenafil for sale canada [url=https://vgrsources.com/#]VGR Sources[/url] female viagra capsule

how can i get viagra without a prescription: VGR Sources – sildenafil generic costs

india viagra generic [url=https://vgrsources.com/#]cost of generic viagra in mexico[/url] 150 mg viagra

viagra generic in mexico: generic viagra paypal canada – sildenafil soft 100mg

https://vgrsources.com/# buy viagra online using paypal

no prescription cheap viagra [url=https://vgrsources.com/#]VGR Sources[/url] generic viagra 2018

generic sildenafil: canadian pharmacy viagra 200 mg – on line viagra

order sildenafil uk: viagra 1500mg – female viagra australia where to buy

where to buy viagra online in india [url=https://vgrsources.com/#]VGR Sources[/url] buy 1 viagra pill

discount viagra usa: VGR Sources – lowest price viagra

https://vgrsources.com/# viagra pill where to buy

best female viagra tablets [url=https://vgrsources.com/#]VGR Sources[/url] generic sildenafil tablets

where can i buy cheap clomid without dr prescription can i get clomid without rx can i purchase generic clomiphene online can you buy clomid online where to get cheap clomid without prescription order generic clomiphene without insurance buying cheap clomid

https://vgrsources.com/# viagra online australia fast delivery

https://vgrsources.com/# real generic viagra

https://vgrsources.com/# viagra buy online canada

This is the amicable of serenity I enjoy reading.

https://vgrsources.com/# Sildenafil 50 mg Indien online

http://semaglupharm.com/# 140 lbs semaglutide 6 week belly ozempic weight loss before and after

https://semaglupharm.shop/# Semaglu Pharm

https://prednipharm.shop/# buying prednisone without prescription

Thanks towards putting this up. It’s well done.

http://prednipharm.com/# prednisone buy cheap

https://prednipharm.shop/# prednisone 10 mg over the counter

https://lipipharm.com/# LipiPharm

http://crestorpharm.com/# Crestor Pharm

azithromycin drug – flagyl order buy metronidazole pills for sale

http://lipipharm.com/# LipiPharm

http://crestorpharm.com/# Crestor Pharm

semaglutide 14mg cheap – order rybelsus 14 mg sale buy periactin online

http://semaglupharm.com/# SemagluPharm

http://semaglupharm.com/# Buy Rybelsus online USA

http://lipipharm.com/# LipiPharm

http://lipipharm.com/# is it better to take lipitor in the morning or at night

reputable indian pharmacies: buy medicines online in india – India Pharm Global

¡Hola, aventureros del desafío !

Casinos extranjeros con pagos automГЎticos y seguros – п»їhttps://casinoextranjerosespana.es/ casinoextranjerosespana.es

¡Que disfrutes de asombrosas premios extraordinarios !

https://indiapharmglobal.com/# India Pharm Global

canadian pharmacy meds: best canadian pharmacy – canada online pharmacy

Your article helped me a lot, is there any more related content? Thanks!

India Pharm Global: buy medicines online in india – top 10 pharmacies in india

certified canadian pharmacy [url=https://canadapharmglobal.com/#]best canadian pharmacy to buy from[/url] canadian pharmacy no rx needed

¡Saludos, participantes de emociones !

GuГa completa de casinos extranjeros para 2025 – https://www.casinosextranjerosenespana.es/ casinos extranjeros

¡Que vivas increíbles jugadas excepcionales !

buying from online mexican pharmacy: Meds From Mexico – Meds From Mexico

buy domperidone online – sumycin brand buy flexeril 15mg sale

purple pharmacy mexico price list: pharmacies in mexico that ship to usa – Meds From Mexico

https://medsfrommexico.shop/# mexico drug stores pharmacies

mexico drug stores pharmacies [url=https://medsfrommexico.shop/#]Meds From Mexico[/url] Meds From Mexico

canadian pharmacy world: Canada Pharm Global – buy drugs from canada

Meds From Mexico: п»їbest mexican online pharmacies – best online pharmacies in mexico

India Pharm Global [url=http://indiapharmglobal.com/#]India Pharm Global[/url] india online pharmacy

reputable canadian pharmacy: Canada Pharm Global – canada pharmacy reviews

mail order pharmacy india: india online pharmacy – India Pharm Global

https://canadapharmglobal.shop/# canadian pharmacy online reviews

mexico pharmacies prescription drugs: Meds From Mexico – mexico drug stores pharmacies

buying prescription drugs in mexico [url=https://medsfrommexico.com/#]Meds From Mexico[/url] п»їbest mexican online pharmacies

medication canadian pharmacy: www canadianonlinepharmacy – my canadian pharmacy reviews

Meds From Mexico: Meds From Mexico – purple pharmacy mexico price list

india online pharmacy: India Pharm Global – buy prescription drugs from india

https://canadapharmglobal.shop/# canadian 24 hour pharmacy

India Pharm Global: India Pharm Global – India Pharm Global

top 10 online pharmacy in india: India Pharm Global – cheapest online pharmacy india

Meds From Mexico: Meds From Mexico – Meds From Mexico

¡Saludos, aventureros de emociones !

Giros gratis en casino online extranjero top – https://www.casinoextranjerosenespana.es/# casinos extranjeros

¡Que disfrutes de logros sobresalientes !

¡Hola, buscadores de riqueza !

Lista de casinos fuera de EspaГ±a sin verificaciГіn – п»їп»їhttps://casinoonlinefueradeespanol.xyz/ casinos fuera de espaГ±a

¡Que disfrutes de asombrosas momentos memorables !

pet meds without vet prescription canada: canadian neighbor pharmacy – canadian drug prices

https://medsfrommexico.com/# reputable mexican pharmacies online

Rask Apotek: Rask Apotek – Rask Apotek

kГ¶pa jodtabletter apotek: laktosintolerans tabletter – vilka apotek finns det

Papa Farma: fisiocrem para que sirve – Papa Farma

¡Saludos, apostadores entusiastas !

casinosextranjero.es – experiencias Гєnicas al jugar – https://www.casinosextranjero.es/# casino online extranjero

¡Que vivas increíbles jugadas excepcionales !

https://raskapotek.shop/# apotek d vitamin

kan man sola med feber: Svenska Pharma – Svenska Pharma

latex hansker apotek: Rask Apotek – Rask Apotek

hemleverans apotek: abort tabletter apotek – menstrosor rea

krillolje apotek: apotek vulkan – medisin pГҐ nett

http://papafarma.com/# Papa Farma

potensmiddel pГҐ apotek: lusekam apotek – Rask Apotek

elidel crema 15 g prezzo: farmacia dr max online – trausan a cosa serve

Svenska Pharma: Svenska Pharma – Svenska Pharma

https://efarmaciait.com/# EFarmaciaIt

apotek Г¶ppna nu: Svenska Pharma – apotej

mycostatin spray: luvion compresse – EFarmaciaIt

Rask Apotek: Rask Apotek – aporek

Svenska Pharma: Г¶gonskydd apotek – vaxpropp apotek

¡Hola, usuarios de sitios de apuestas !

Casinos online extranjeros que pagan en 1 hora – https://www.casinoextranjero.es/ mejores casinos online extranjeros

¡Que vivas victorias legendarias !

https://efarmaciait.shop/# algix compresse prezzo

urixana a cosa serve: mycostatin costo – EFarmaciaIt

kakao barn: Svenska Pharma – apotek glasГ¶gon

var kan jag kГ¶pa: Svenska Pharma – Svenska Pharma

apotek nettbutikk fri frakt: Rask Apotek – Rask Apotek

http://svenskapharma.com/# kaliumpermanganat apotek

Papa Farma: Papa Farma – cepillo oral b io

EFarmaciaIt: EFarmaciaIt – EFarmaciaIt

I blog quite often and I truly appreciate your content. The article has truly peaked my interest. I am going to book mark your site and keep checking for new details about once per week. I opted in for your Feed as well.

¡Bienvenidos, expertos en el juego !

Casino fuera de EspaГ±a sin documentaciГіn – https://www.casinoporfuera.guru/ casinos fuera de espaГ±a

¡Que disfrutes de maravillosas premios asombrosos !

Papa Farma: farnacias – toallitas dodot

https://papafarma.shop/# movicol pediГЎtrico con leche

Svenska Pharma: Svenska Pharma – Svenska Pharma

contatto scalapay: EFarmaciaIt – gentamicina crema parti intime uomo

PharmaJetzt: PharmaJetzt – apotheke online versandkostenfrei

wegovy online apotheke: Pharma Jetzt – apotal versandapotheke online apotheke

https://medicijnpunt.shop/# recept medicijnen

viata online apotheek: belgische online apotheek – medicijnen bestellen online

tapis de bain absorbant: fleur de bach arthrose – tadalafil 10 mg prix

Lovely just what I was looking for.Thanks to the author for taking his time on this one.

doxycycline tesco pharmacy: Pharma Connect USA – Pharma Connect USA

recept medicijn: online pharmacy nl – MedicijnPunt

http://pharmajetzt.com/# PharmaJetzt

Pharma Connect USA: target pharmacy hours – good rx pharmacy discount card

lon: ggp: quel est le meilleur site de pharmacie en ligne ? – Pharma Confiance

online pharmacy scams: enalapril online pharmacy – PharmaConnectUSA

https://pharmaconnectusa.shop/# Pharma Connect USA

tylenol 3 pharmacy name: PharmaConnectUSA – PharmaConnectUSA

Pharma Confiance: pharmacie des graves – Pharma Confiance

¡Saludos, jugadores apasionados !

GuГa 2025: casinos fuera de EspaГ±a con pago rГЎpido – п»їhttps://casinosonlinefueraespanol.xyz/ casinos online fuera de espaГ±a

¡Que disfrutes de logros impresionantes !

Pharma Confiance: berocca logo – avis newpharma

luidpold apotheke: 0nline apotheke – Pharma Jetzt

http://pharmajetzt.com/# apotheke online deutschland

apotal versandapotheke online: shop apptheke – Pharma Jetzt

¡Hola, participantes del desafío !

Casino online extranjero ideal para jugadores high roller – https://casinosextranjerosdeespana.es/# п»їcasinos online extranjeros

¡Que vivas increíbles giros exitosos !

Pharma Connect USA: mexican pharmacy fluconazole – spironolactone inhouse pharmacy

¡Bienvenidos, amantes del riesgo !

Casino fuera de EspaГ±a sin documentos oficiales – https://www.casinofueraespanol.xyz/ п»їп»їcasino fuera de espaГ±a

¡Que vivas increíbles éxitos notables !

appotheek: med apotheek – MedicijnPunt

apotheek inloggen: mijn medicijn bestellen – Medicijn Punt

avis sur clinique vГ©tГ©rinaire normandia: tadalafil 20 mg prix – Pharma Confiance

https://pharmaconnectusa.shop/# us cialis online pharmacy

Pharma Confiance: le stick de mon pharmacien – Pharma Confiance

low dose naltrexone online pharmacy: PharmaConnectUSA – PharmaConnectUSA

online pharmacy atorvastatin: PharmaConnectUSA – Himplasia

humana online pharmacy login: nizoral online pharmacy – PharmaConnectUSA

https://pharmaconfiance.com/# Pharma Confiance

uw apotheek: Medicijn Punt – mijn medicijnkosten

Pharma Jetzt: online apotheke deutschland – pzn apotheke

protГЁge fauteuil 1 place: Pharma Confiance – Pharma Confiance

fantastic publish, very informative. I wonder why the opposite specialists of this sector do not understand this. You should proceed your writing. I am confident, you have a great readers’ base already!

MedicijnPunt: medicijnen online kopen – apotheek medicijnen bestellen

?Hola, exploradores del azar !

Mejores casinos fuera de EspaГ±a sin restricciones – https://casinosonlinefueradeespanol.xyz/# casino por fuera

?Que disfrutes de asombrosas logros notables !

gГјnstige apotheke: gГјnstige online apotheke auf rechnung – PharmaJetzt

http://pharmajetzt.com/# Pharma Jetzt

gloire grace: Pharma Confiance – Pharma Confiance

PharmaJetzt: beste online apotheke – PharmaJetzt

apotheke nl: apotheke online – apteka holandia

MedicijnPunt: Medicijn Punt – uw apotheek

http://medicijnpunt.com/# beste online apotheek

Medicijn Punt: apteka online holandia – Medicijn Punt

viagra avant ou aprГЁs repas: Pharma Confiance – crГЁme solaire avene que choisir

landelijke apotheek: MedicijnPunt – MedicijnPunt

Pharma Jetzt: nutrim erfahrungen – Pharma Jetzt

https://medicijnpunt.com/# MedicijnPunt

pharmacy mistake methotrexate: PharmaConnectUSA – generic cialis pharmacy online

Hello admirers of clean lifestyles !

Best Smoke Air Purifier – Best Price Deals – п»їhttps://bestairpurifierforcigarettesmoke.guru/ best air purifiers for smoke

May you experience remarkable pristine moments !

apotheek recept: apteka holandia – Medicijn Punt

digitale apotheek: europese apotheek – MedicijnPunt

http://pharmajetzt.com/# Pharma Jetzt

internet apotheken ohne versandkosten: europa apotheek – apotheke online bestellen

Pharma Connect USA: top online pharmacy – PharmaConnectUSA

Pharma Jetzt: shop apotheke versandkostenfrei – Pharma Jetzt

internet apotheke deutschland: luitpold apotheke bad steben online-shop – Pharma Jetzt

clindamycin uk pharmacy: PharmaConnectUSA – claritin d online pharmacy

http://pharmaconfiance.com/# daflon 1000 prix pharmacie

Hey there! I just wanted to ask if you ever have any issues with hackers? My last blog (wordpress) was hacked and I ended up losing a few months of hard work due to no data backup. Do you have any solutions to stop hackers?

PharmaConnectUSA: Pharma Connect USA – eckerd pharmacy store locator

Pharma Jetzt: schopapoteke – europaapotheek

viagra pharmacy coupons: propecia uk pharmacy – PharmaConnectUSA

Medicijn Punt: apotheek zonder recept – MedicijnPunt

https://pharmaconnectusa.shop/# tesco pharmacy viagra cost

apotheke obline: PharmaJetzt – PharmaJetzt

men’s health pharmacy viagra: Pharma Connect USA – online pharmacy pain relief

esomeprazole 20mg generic – anexa mate esomeprazole 40mg sale

para pharma: Pharma Confiance – Pharma Confiance

¡Hola, jugadores expertos !

Casinosinlicenciaespana.xyz con tragamonedas exclusivas – https://casinosinlicenciaespana.xyz/# casino sin licencia espaГ±a

¡Que vivas increíbles instantes únicos !

afbeelding medicijnen: medicijnlijst apotheek – Medicijn Punt

mijn medicijnen bestellen: Medicijn Punt – Medicijn Punt

https://pharmajetzt.com/# PharmaJetzt

fluconazole tesco pharmacy: actos online pharmacy – online pharmacy zyprexa

farmacie medicijn: Medicijn Punt – wat is mijn apotheek

provigil india pharmacy: PharmaConnectUSA – Pharma Connect USA

https://medicijnpunt.com/# Medicijn Punt

PharmaJetzt: onlinr apotheke – medikamente liefern lassen

warfarin 5mg over the counter – coumamide losartan 50mg sale

online drugstore netherlands: apotheek zonder recept – recept medicijn

Valuable information. Lucky me I found your website by accident, and I am shocked why this accident did not happened earlier! I bookmarked it.

https://pharmajetzt.com/# billig medikamente

Pharma Confiance: verre normandie 11 cl – medium calvados

PharmaConnectUSA: imiquimod cream online pharmacy – humana rx pharmacy

apotheek spanje online: betrouwbare online apotheek – apteka internetowa holandia

https://medicijnpunt.com/# medicijnen bestellen online

¡Hola, seguidores de la aventura !

Casinos sin licencia en EspaГ±a con criptoactivos – https://casinosonlinesinlicencia.es/# casino online sin registro

¡Que vivas increíbles giros afortunados !

PharmaJetzt: PharmaJetzt – PharmaJetzt

¡Saludos, descubridores de riquezas secretas !

Juegos en casino sin licencia sin procesos largos – http://www.emausong.es/ casino sin licencia espaГ±a

¡Que disfrutes de increíbles instantes memorables !

Pharma Confiance: Pharma Confiance – pharmacie ouverte Г cannes aujourd’hui

Thank you, I have just been searching for info about this subject for ages and yours is the best I’ve discovered till now. But, what about the bottom line? Are you sure about the source?

MedicijnPunt: MedicijnPunt – Medicijn Punt

http://pharmaconnectusa.com/# Pharma Connect USA

you could have an amazing weblog here! would you prefer to make some invite posts on my blog?

mexican drugstore online: TijuanaMeds – mexican online pharmacies prescription drugs

IndiMeds Direct: IndiMeds Direct – IndiMeds Direct

https://canrxdirect.shop/# best canadian online pharmacy

meloxicam 7.5mg brand – https://moboxsin.com/ meloxicam 7.5mg over the counter

TijuanaMeds: TijuanaMeds – TijuanaMeds

TijuanaMeds: buying from online mexican pharmacy – mexican pharmaceuticals online

http://indimedsdirect.com/# IndiMeds Direct

http://tijuanameds.com/# TijuanaMeds

india pharmacy mail order: top 10 pharmacies in india – india pharmacy mail order

canadian medications: CanRx Direct – canadian drug pharmacy

Just desire to say your article is as astonishing. The clarity for your post is simply excellent and i could suppose you’re a professional in this subject. Well together with your permission allow me to grasp your RSS feed to stay up to date with imminent post. Thank you a million and please carry on the gratifying work.

https://tijuanameds.shop/# TijuanaMeds

indian pharmacy online: IndiMeds Direct – IndiMeds Direct

Greetings, followers of fun !

Funny adult jokes with a naughty little twist – https://jokesforadults.guru/# great jokes for adults

May you enjoy incredible epic punchlines !

canadian pharmacy: CanRx Direct – escrow pharmacy canada

https://canrxdirect.com/# canadian pharmacy 24h com safe